Quality Standards

The rapid growth for roofing and cladding in traditional hard metals has seen an increasing number of building designs incorporating zinc, stainless steel, aluminium and copper. Whilst welcomed by a resurgent UK construction industry, this increasing demand has exposed an alarming skills gap in those taking on the responsibility for design and installation in traditional metal roofing.

As a result, general roofing and cladding contractors with little or no knowledge or experience of traditional metal roofing techniques have been attracted by the increasing demand for installers, and this alarming trend has been damaging the industry. Poor design, detailing and workmanship are affecting an increasing number of projects and the Federation has been alerted to a number of projects where this had led to roof failure. As a result, an increasing number of clients and main contractors are now recognising the long-term value of engaging experienced specialists and are nominating FTMRC members in their tender documentation.

As would be expected, the trade association that represents installers with high workmanship values has a similar uncompromising attitude towards quality standards.

Quite simply, it doesn’t matter how large a company is or how much money they have, if the quality of their metal roof installations does not meet the minimum standard required, they cannot become a member of the FTMRC

This has commercial significance in view of the increasing number of major project specifications that include the instruction that the metal roofing and cladding work is to be carried out by a member of the FTMRC. It also has significance for the manufacturing associate members of the Federation that rely upon the quality of the installer to maximise the performance of their product.

And not least it provides peace of mind for the client that an organisation is taking the responsibility for constantly checking the standard of work of its members.

We Take Quality Control Seriously

The FTMRC take pride in the quality of the work carried out by their members, but those standards are rigorously policed because, quite frankly, our reputation (and theirs) depends on it.

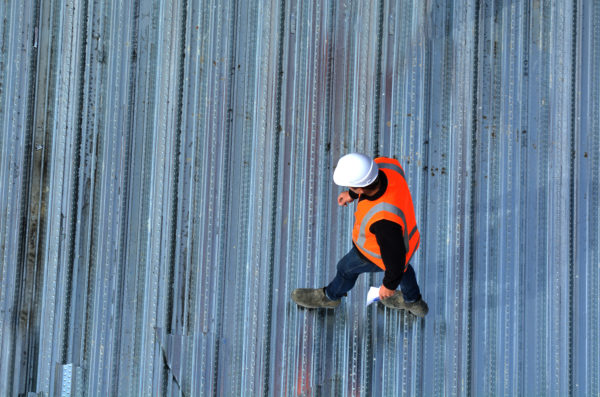

Standards of design and workmanship are not left to chance and there is an organised programme of on-site inspections carried out involving each member to ensure they are maintaining their commitment to the quality expected of members of the FTMRC.

Members’ work is inspected and graded on a regular basis, with the frequency of future inspection determined by the grade achieved. As a result of a recent decision by the Council, from 2019 members’ grades will be published.

Inspections are carried out by our experienced technical consultants and take place on the roof (not from the car park!) for a close-up view so the design detail and the quality of installation can be properly assessed. Any detail that does not conform to the Guide to Good Practice must be addressed and corrected or the contractor could forfeit their Federation membership.